CO2 Emissions

Water Use

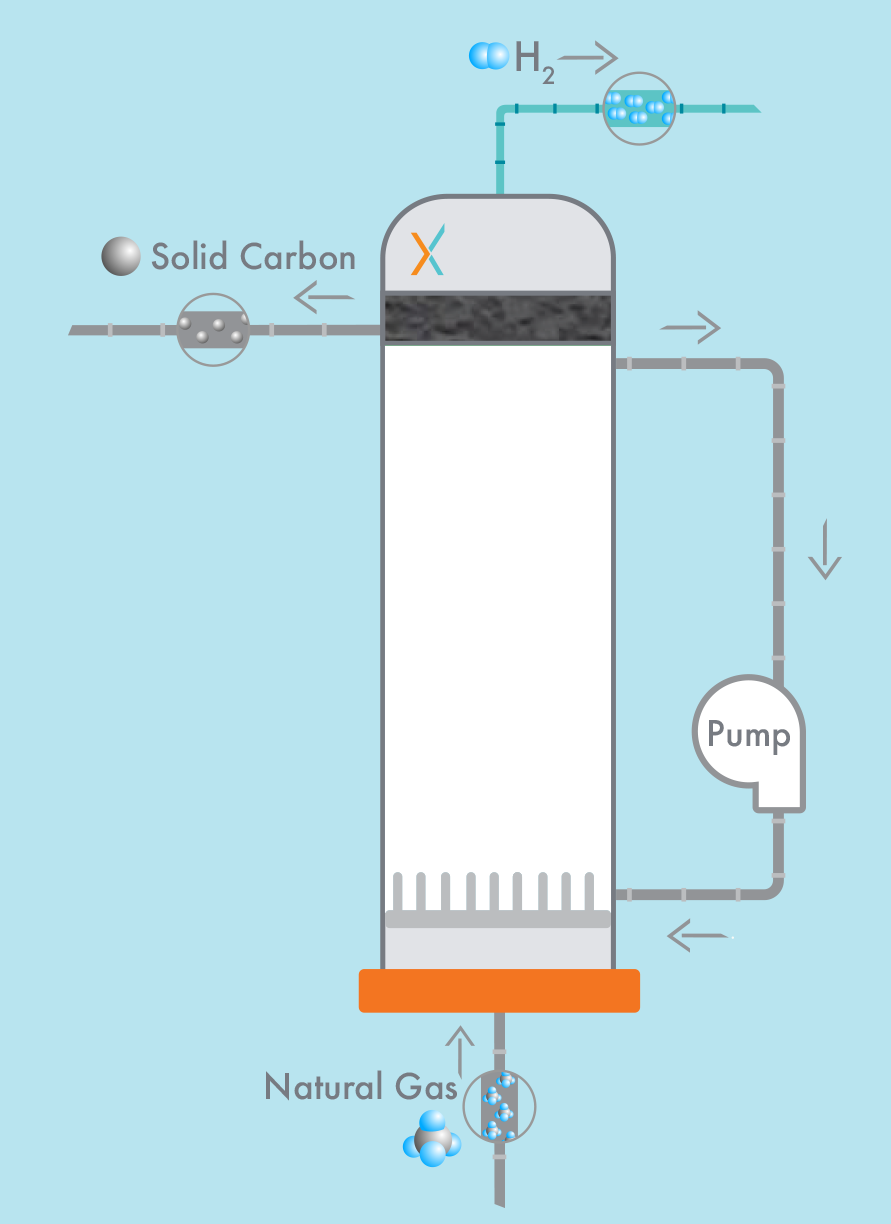

We are proud to offer affordable and low-emission hydrogen and solid carbon. Through our advanced pyrolysis process, we have perfected the transformation of natural gas into its fundamental components.

Using a bubbling technique and our state-of-the-art molten metal recirculation system, we introduce natural gas from the bottom, passing it through molten metal to ensure consistent and efficient output. The reaction that occurs in this high-temperature and oxygen-free environment converts the natural gas into its basic constituents: hydrogen and solid carbon. This process, known as pyrolysis, is key to our efficient production method.

Following the reaction, we extract the solid carbon from the reactor, ensuring its purity and quality for various applications. Meanwhile, the hydrogen rises to the top of the reactor and is collected for further use.

Targets

Less GHG

Production

Utilized

Utilized

Installation

Low-Emission Hydrogen Production

Copyright ©2024 VulcanX ® | Design by A.Alizadeh